ASSEMBLY

Precision Metal Fabrication can provide and install any type of hardware your project calls for. From fasteners to casters to rivets, we’re able to provide the assembly and installations your project needs.If your project calls for specialized crates, pallets or packaging we have a dedicated wood shop to custom build any crate or shipping container to ensure your project arrives safely and securely. With the skill of our team and the use of the latest equipment and tooling we can help to ensure the end-product has the assembled hardware to increase our customer’s capacity.

- Haeger Pemserter™ 618 Plus Clinch Nut and Stud Press Machine

- Bridgeport® Milling Machine (3)

- Single Spindle Drill Press (7)

- S&L Tapping Arm Table Stations (3)

- Yellow Jacket 110 Orbital Stretch Wrapper Machine

- Custom pallet and crate building department

CNC LASER CUTTING

Precision Metal Fabrication’s CNC laser cutting capabilities help align our philosophy of speed, quality and delivery in a single piece of machinery. Capitalizing on the laser cutting advantages of no warping, fast set up times, endless customization, and clean-cut edges – we provide precise, exceptional products every time.Our 6000-watt MAZAK® 3015 Fiber Laser cuts from 0.10 to 1.00 thick materials and process sheets up to 5 feet by 10 feet in aluminum, cold-rolled steel, hot rolled steel, and stainless steel.

- 6000 watt MAZAK® 3015 Fiber Laser

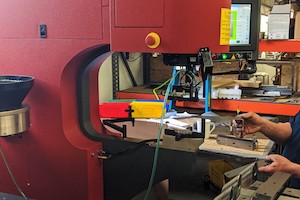

CNC PUNCHING

Precision Metal Fabrications’ CNC turret punches offer the production flexibility necessary to produce customer products that fall into a vast range of requirements. From profiles, to extrusions, beads, louvres, and products with small to large amounts of holes – our turret punches deliver with speed and accuracy to produce production quality parts every time.

- 30 ton Amada® PEGA 345 Turret Punch. 44 Stations 50” x 40” Bed Size

- 30 ton Amada® VIPROS 357 Queen. 54 Stations 72” x 50” Bed Size

- 30 ton Whitney single station punch CNC X&Y gauges

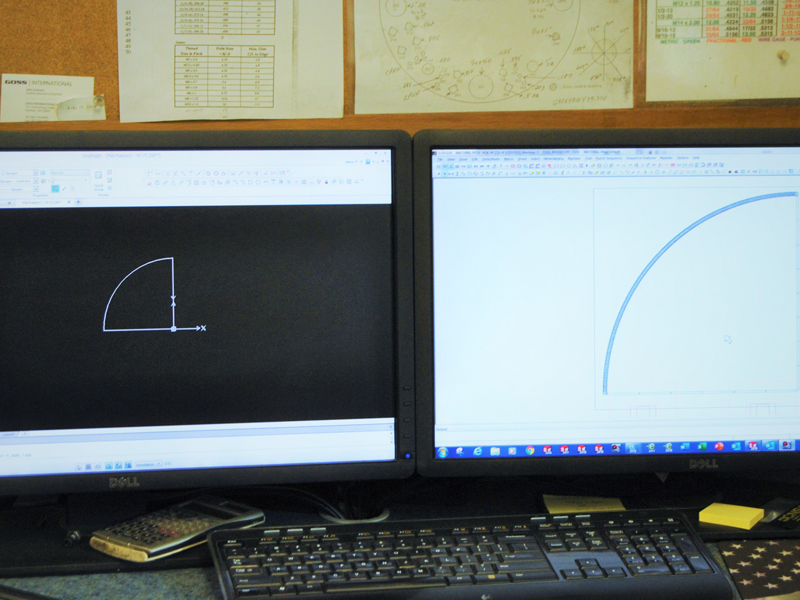

DESIGN SUPPORT

Precision Metal Fabrication’s experienced CAD/Design team can provide concepts, design changes, enhancements, and reverse engineering utilizing the latest CAD software.

Our CAD/Design team is unique in that we not only have the experience in CAD software but we also have many years on the fabrication side. Having this expertise allows us to simplify the manufacturing process and to partner with our customers to better develop and refine their product designs.

We can import and unfold 3D models (.dwg, .step, .sldprt, .dxf ) built in Solid Works. The model is unfolded and downloaded directly into our CAM software for processing in our punches and laser machine.

- Solidworks 2019™ 3D software, AP100 Nesting Software networked with Amada® Turret Punches,

RADAN™ Laser Software networked to MAZAK™ laser cutting machine, DraftSight® 2D CAD.

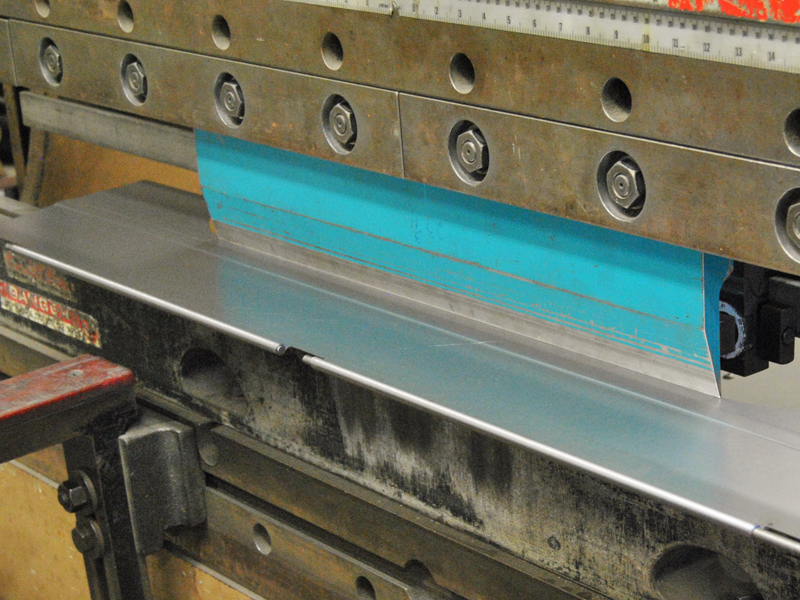

FORMING

From a single bend, to complex multiple bends in nearly any type of material, Precision Metal Fabrication utilizes an unprecedented 8 press brakes – all equipped with the latest 2 axis back gages, operation software and tooling. Having multiple press brakes from 60 ton to 175 ton, tube & pipe bender, initial pinch plate roll machine, and the skill and expertise of our fabricators, we can expertly form a wide array of products with speed and precision.

- 10’ – 175 ton Accupress® with 2 axis Hurco back gauge press brake

- 10’ – 175 ton Cincinnati® FM2 with 2 axis back gauge press brake (2)

- 8’ – 90 ton Cincinnati® Autoform with 2 axis back gauge press brake

- 8’ – 60 ton Accupress® with 2 axis Hurco back gauge press brake

- 10’ – 90 ton Cincinnati® FM2 with 2 axis back gauge press brake

- 6’ – 60 ton Cincinnati® CB2 with 2 axis back gauge press brake

- 4’ – 60 ton Cincinnati® Proform with 2 axis back gauge press brake

- JMT® MRB 2004 Initial Pinch Plate Roll machine 4’ x 3” diameter capacity

- Waldemar® AR31 Tube & Pipe Bender

LARGE PLATE & STRUCTURAL FABRICATIONS

We understand the challenges associated with manufacturing large, complex steel components, equipment, and structures. Our on-site plate and structural division, Weldments Inc. creates solutions for those large fabrication challenges.Our full-time skilled & certified structural and plate tradesmen fabricate and build in a wide range of industrial materials including steel plate, stainless steel, iron and carbon alloy. Our AWS-certified welders utilize MIG,TIG, inner and outer shield arc welding, and oxy acetylene cutting and burning. Our capacity and experience allows us to fab projects of all shapes & sizes including prototypes and specialty runs.

- Weldments Inc.

PAINTING

Precision Metal Fabrication operates two paint facilities – eliminating the need to subcontract the finishing portion of your project and allowing us to ensure our high-quality standards are met by keeping this process in house.We offer a complete line of spray finishes with expertise in texture consistency, chip matching, masking, and surface correction with filling dents, seams, blemishes, and imperfections. We utilize many different coatings from polyurethane enamels, epoxies, Polane, polyester building primers, and clear coats. We’re known for our high-quality finishing with many of our previous projects located in some of the most prominent museums, sports stadiums, and airports located throughout the country.

- 2 – Paint Booths with 1.5 million BTU heating units for wet coat finish.

PROTOTYPING

During the prototyping phase, the main goal is to achieve a seamless transition from prototype to production.

Precision Metal Fabrication is built for delivering production-caliber prototypes that allows for a true assessment of design, application, and materials.

Everything from engineering support, to small production test runs, we’ll be with you every step of the way. With our large inventory of common materials and gauges, and our team of programmers, inspectors, and extensive tooling list we can expedite your prototypes with exceptional quality.

SANDING & GRINDING

Sanding and grinding are essential elements to a great looking, quality part. We have the tools and skills to perform many forms of metal finishing on most metals including stainless steel.

Whether sanding to remove burrs or grinding to smooth welds, PMF can go above and beyond with custom grains and decorative finishes.

Our skilled craftsmen have the expertise to finish projects for the food and beverage industry, decorative looks for trade show and museum exhibits and provide proper surface condition prep to ensure better paint adhesion.

- Baldor® Pedestal grinder/buffer stations (8)

- Dual Station 6” x 4’ Belt Sander (2)

- Dust & Fume Extractor Grinding Stations (2)

- Timesavers® LYNX Series wet metal finisher

SHEARING

The sheet material we stock and use in many of our fabrications comes in sheets of 4’ x 10’. Those sheets are then sheared into blanks to be punched or laser cut in Precision Metal Fabrication’s state-of-the-art equipment. With our shears we can quickly & effectively shear strips, blanks, or plates from many different materials and thicknesses up to ¼’’.

- 2- Cincinnati® Squaring Shears – 10’ x ¼” thick mild steel

WELDING

Welding requires a high level of skill and expertise. At Precision Metal Fabrication, we have both.

Our team of experienced welders use the latest equipment to handle your most demanding needs. Our extensive welding department uses a variety of welding procedures including MIG, TIG, and resistance spot welding and will ensure the proper technique is used to produce a quality product every time. We work closely with our customers to understand their exact needs and can cost-effectively engineer weld fixtures to achieve the precise alignment and tolerances, producing the highest quality fabrications.

- Lincoln® MIG welders to 250 amps (18)

- Lincoln® TIG welders to 350 amps (6)

- Miller® TIG welders to 350 amps (2)

- Miller® 141 Millermate™ portable MIG welder (4)

- Miller® portable spot welder

- Panelspotter spot welder

- Erico® PW portable stud welder (2)

- 75 KVA spot welder (2)